China fiber optic Factory

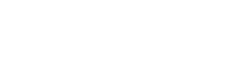

Visual Fault Locators

Visual Fault Locator Manufacturer, Direct Sales from Factory

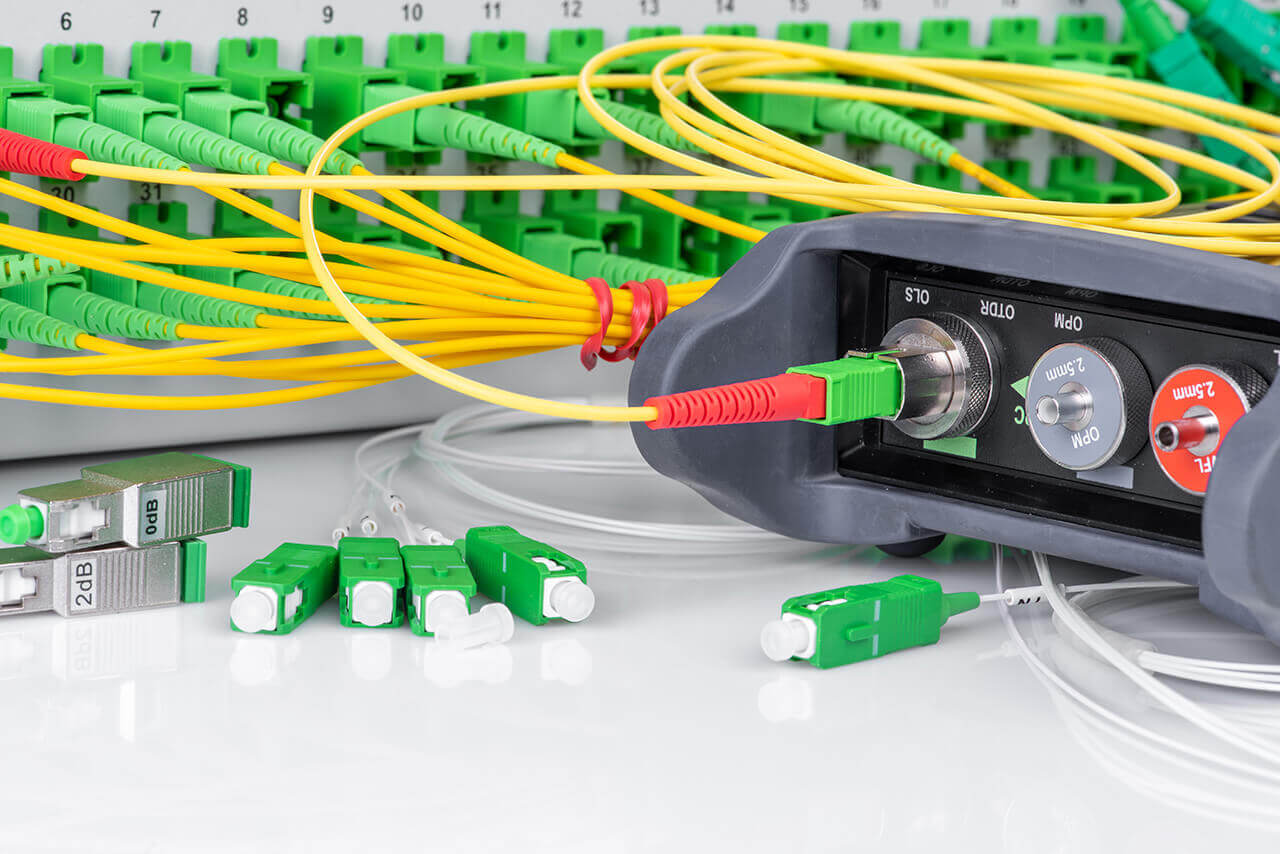

DATA CENTER CABLING

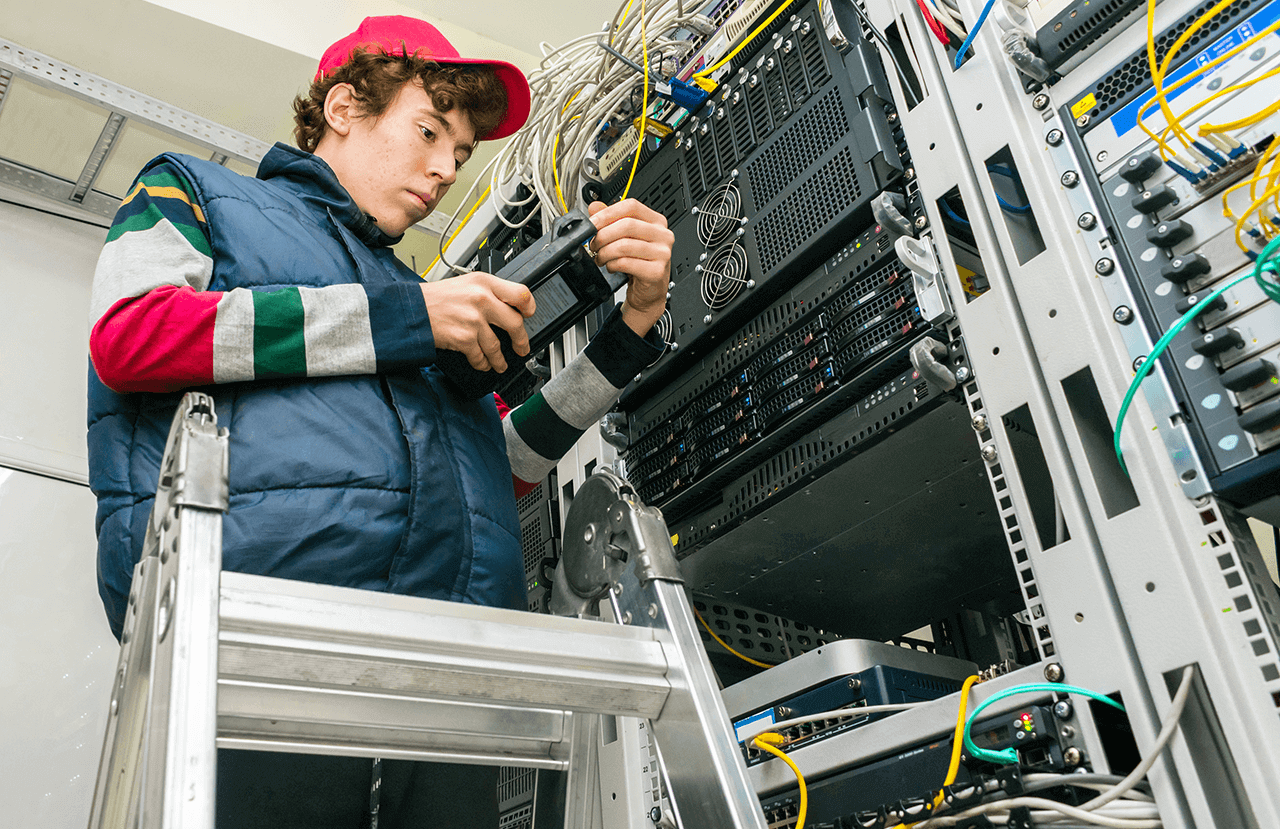

fiber to the home

fiber to the antenna

How to: Use Visual Fault Locator (VFL)

Visual Fault Locator Lasers – How Much Power Shall I use?

How does visual fault locator work?

Another example of how to use visual fault locators

A Visual Fault Locator (VFL) is an essential tool in every fiber optic tool kit. It’s also one of the least expensive tools in the kit. VFL will allow you to quickly identify breaks or macrobends in fiber and identify poor splices in multimode or single mode fiber.

The biggest difference between a continuity tester and a VFL is the light sources they use and the light output power of the light sources. VFL usually uses red visible light (635-650nm) laser light source, and the optical output power of the laser is usually 1mW or less. You can see red light with the naked eye, but due to the high light output power, you should remember not to look directly at the output of the VFL.

VFLs come in different shapes and sizes. Some may look like a pen, some may look like a small box. Others may be built into an optical time domain reflectometer (OTDR) or other test equipment. Huihong Fiber has pen type and box type visual fault locator.

When at work, a VFL fills the fiber core with light from a laser. Light from the laser escapes the fiber when it breaks or macroscopically bends. Light escaping from the fiber will normally illuminate the buffer surrounding the fiber. Depending on the jacket color, thickness, and other structure factors, breaks may not always be visible through the jacket of fiber optic cables. Macro bending is not always visible through the sheath, but is usually visible through the buffer zone.

The visual fault locator has many uses, but its most common usage is to detect the connectivity of the optical fiber and locate the fault point of the optical fiber, so how to use the visual fault locator? The visual fault locator has two working modes: a constant light mode, which can stably show the connectivity of the fiber jumper through continuous light; and a flashing mode, which quickly finds out the fault point of the fiber through the flashing light.

The specific usage is as follows:

1. Install the battery and check whether the visual fault locator is in good condition

Unscrew the pen head and body of the visual fault locator, install the battery in the body of the visual fault locator (pay attention to the positive and negative poles of the battery), tighten the pen head and the pen body after the battery is installed, and open the dustproof of the visual fault locator Cap and control switch, observe whether the visual fault locator has red light, if there is red light, it means that the visual fault locator is installed correctly and can be used;

2. Select the appropriate connector according to the type of fiber optic jumper

Select the appropriate connector according to the type of fiber jumper (that is, the interface type of the fiber jumper), such as LC fiber jumper, choose the LC connector to install on the interface of the visual fault locator, and then insert the fiber jumper into the connector of the visual fault locator (Please use a cleaning tool to clean the interface of the optical fiber jumper before inserting it);

3. Turn on the working mode of the visual fault locator to detect the fiber jumper

First select the constant light mode of the visual fault locator (push up), and check whether the fiber jumper is connected and intact through continuous light. If there is no red light leakage in the fiber jumper, it means that the fiber jumper is intact. If there is a red light leakage somewhere, turn on the flashing mode of the visual fault locator (push down), and quickly find out the fault point of the fiber optic jumper through the flashing light. If the fiber jumper is damaged due to excessive bending of the fiber, just replace the fiber jumper. If the fault point of the fiber jumper is the fiber fusion joint, there may be air bubbles in the fusion joint, and the fiber needs to be re-spliced.

Precautions for using the visual fault locator

1. The laser is harmful to the eyes, so when using the visual fault locator, avoid direct laser light to the eyes;

2. When using the visual fault locator, it is best to clean the fiber jumper interface with a cleaning tool;

3. Usually, the service life of the laser will be shortened in the high temperature working environment, so the visual fault locator should try to avoid the high temperature working environment;

4. After using the visual fault locator or not using it for a long time, in order to avoid dust, oil and other pollution, it is necessary to wear a dust cap in time;

5. In order to avoid battery rot and damage to the visual fault locator, please take out the battery in time when the visual fault locator is not used for a long time.

Huihongfiber visual fault locator has strong light concentration and small attenuation, and can easily penetrate 8~10km of optical fiber to detect faults such as broken and bent optical fibers. It can also calibrate the optical attenuator and light source; in addition, the huihongfiber visual fault locator interface belongs to The standard 2.55mm interface can be connected to SC/FC/ST optical fiber interface, and there is also an optional optical fiber converter, which can be used to connect to 1.25mm optical fiber interface. Huihongfiber visual fault locator is easy to use and operate. It can detect and locate the fiber end point through the red light emitted. It is one of the necessary fiber detection tools for on-site construction and fiber maintenance personnel.

Thank you for your inquiry

Huihongfiber company has long been committed to the research and development and production of optical communication devices and equipment. It is a high-tech enterprise integrating development, mass production and sales. The company provides a large number of optical passive devices and related equipment, the products covering fiber optic cable assemblies, optical cables, transceivers, closures and testers. The company adopts advanced production and testing equipment to provide users with stable and high-quality products, which are widely used in major domestic operators and exported in batches overseas, since 1995 we have won good reputation from users. We adhere to the service tenet of high quality, low price, fast delivery and good service. Huihongfiber sincerely hopes to become your partner too.